The Sales and Operations Planning (S&OP) process enables synchronisation in supply chain management by integrating an organisation's supply, demand, new product plans, sales strategies, manufacturing operations and capacity management. However, on the way to S&OP maturity, the organisation faces various challenges in implementing strategies and managing actions related to processes, people, technology and monitoring.

With extensive experience in supply chain optimisation, proven successful results in implementing and improving S&OP processes, and extensive knowledge in retail solutions, Wysupp's team of consultants help organisations overcome these challenges and reach the highest level of maturity by implementing technological supply chain solutions, integration services and strategic consulting.

Sales & Operations alignment requires Structured Strategies

The main objective of the S&OP process is to enable the company to integrate a business management process that enables management to focus on the key supply chain drivers, including sales, marketing, demand management, production, inventory management, financial performance analysis, new product introduction, human resource management and capacity constraint assessment.

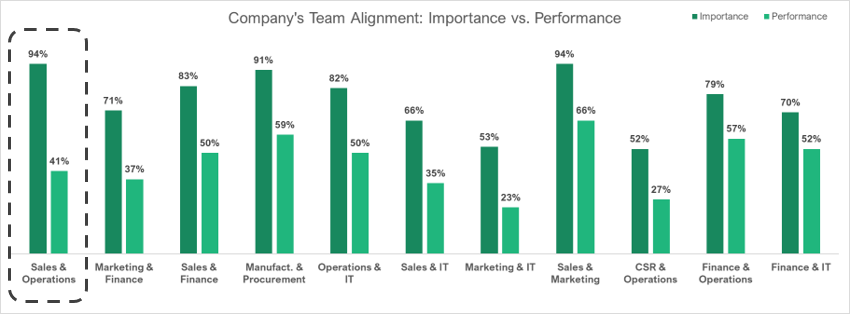

It is therefore necessary and important that there is maximum alignment between Sales and Operations to ensure that the strategies followed during the processes involved in S&OP and the decisions made are linked to the optimal outcomes of the outputs of these drivers. However, research among manufacturers, retailers, logistics providers, consultants and other business models shows that the biggest gap in organisations is in the alignment between sales and operations teams:

Source: Supply Chain Insights LLC, Race for Supply Chain 2020 Study (Base: Manufacturers, Retailers, 3 Third Party Logistics Providers, Consultants and Software Providers)

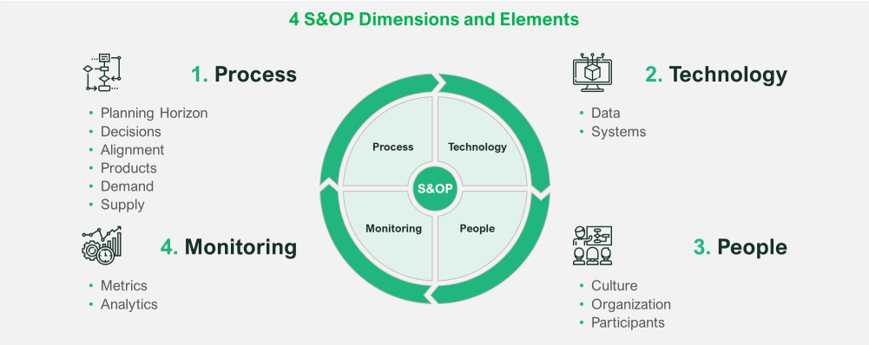

The alignment gap between Sales and Operations can be closed by the outcome of structured strategies implemented to achieve a robust and effective S&OP based on the 4 process dimensions and its fundamental elements.

4-Dimension Major Challenges

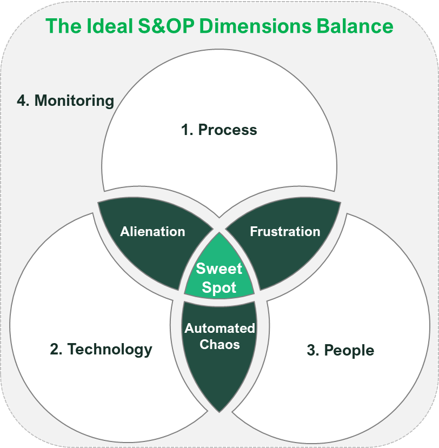

The major challenges of an organisation in terms of S&OP are related to achieving the ideal balance of process dimensions according to the current maturity level, business requirements and defining the appropriate strategies to achieve the targeted maturity level.

The major challenges of an organisation in terms of S&OP are related to achieving the ideal balance of process dimensions according to the current maturity level, business requirements and defining the appropriate strategies to achieve the targeted maturity level.

An organisation that has a well-established process and committed people but does not have the appropriate technology for S&OP management will create frustration. Conversely, organisations with dedicated staff and appropriate technology will always be mired in automated chaos without a well-structured and defined S&OP process. Finally, even a mature S&OP process with the most advanced technology systems, but without staff commitment, the organisational culture for S&OP collaboration and the right participants, will create alienation.

The sweet spot, which we can also call the "art and science of S&OP change management", depends on the balance of all these 3 dimensions (Process, Technology and People) and the fourth-dimension Monitoring, when every S&OP process step and success measurement must be strategically balanced between cost, cash and service and directly linked to business KPI's to achieve strategic goals and maturity targets.

Strategies based on S&OP Elements to address the Challenges

An effective approach to addressing the S&OP challenges, identifying the current pain points and assessing the GAPs in relation to the targeted maturity level of the process is to define segmented strategies for each of the elements that make up the dimensions of the process.

These elements are outlined below, along with best practices and strategy guidelines for achieving a robust and effective S&OP process:

1. Process

The first dimension refers to the process itself. In order to achieve the organisation's strategic objectives and overcome challenges, the S&OP must be an established, well-structured and recognised formal process. Collaboration is key to the process and must drive strategic relationships with internal teams and external trading partners to create overall value for the network.

The process needs to be a fully integrated forum to support decision making across business functions and time horizons. Some 'what if' scenarios should provide insight into benefits and the process may include playbook outputs or potential responses. Some range forecasting or other ways to identify uncertainties should be enabled by the process, as well as the ability to try to seize opportunities with segmented responses.

To maintain alignment between all high levels of management in the organisation, the S&OP owner, the process participants, the divisions involved and external partners, it is critical to establish a governance model, effective communication processes and regular integrated steps for each part of the overall cycle. Information flows to and from other process steps and needs to be linked to strategic plans and deliberated in executive reviews.

A mature S&OP process that is able to provide the organisation with the best tools to make the best decisions in the short, medium and long term, anticipate strategies for potential problems, avoid costs and mitigate risks must have a 'mostly forward looking' focus. The planning horizon must be longer than the overall lead time and look 12 months into the future, with a focus on long-term strategic plans for the supply chain.

The S&OP information flow process, steps and management meetings should consider all the elements listed above. The first steps of the phase should be linked to the business targets for the next periods (e.g.: Increase margin, increase sales without price erosion, or reduce inventory and waste) and a structured demand planning process to develop a consensus unconstrained forecast with best- and worst-case scenarios.

To be aligned with sales, marketing and R&D strategies, the process must include a structured stage gate to improve product transitions and reduce obsolete inventory, and a portfolio review including segmentation.

In terms of operations, the process steps must include a review of unconstrained demand forecasting, supply constraints, inventories, and risks and opportunities. Capacity planning and workforce management must be key process steps to ensure balance between supply and demand, identification of gaps and alignment between supply chain and operational strategies.

2. Technology

Most S&OP professionals consider technology to be an extremely critical or very critical part of their organisation's S&OP process and they believe that their companies will invest more in the coming years than in previous years.

This is because the availability of big data from the functions involved in the S&OP process, the need for systems to support demand forecasting and collaboration processes, as well as systems to manage operations and decision-making, require companies to invest more and more in technologies such as cloud computing, demand forecasting and collaboration, Big Data / Analytics and artificial intelligence.

A robust S&OP requires established master data management and governance models and processes that view data as a competitive advantage and ensure that relevant information is leveraged for better network visibility. A central data warehouse should store structured data from a variety of sources - internal and external.

The S&OP process relies on technology to support process flow, scenario modelling and demand modelling across time horizons and the network. Therefore, in addition to master data management, companies need integrated supply chain optimisation systems with transactional data set, machine learning algorithms and forecast-driven tools and reports that enable and improve demand forecasting, replenishment strategies, inventory optimisation and financial reconciliation.

As a RELEX partner, Wysupp implements best-in-class solutions in the areas of Demand Forecasting, Replenishment, Integrated Supply Chain, Allocation, KPIs Management, Master Data Management, Fresh Optimisation and Promotion Forecasting.

3. People

Human and organisational factors are key to the maturity development of the S&OP process from the initial implementation stage to the best-in-class stage.

To achieve the best results on performance KPIs, S&OP must be an important part of the organisation. Not only does the process need to be well structured, but it also needs to be highly valued in order to add value. Teams should be specialised and roles should be based on core competencies and business needs. Formal internal and external training programmes that enable continuous development must always take place.

In order to collectively overcome daily challenges and continuously improve the process, employees must seek common direction and holistic solutions, and these ideals must be promoted and cultivated. Therefore, it is necessary to create and maintain a culture of trust and collaboration where cross-functional teams share information and there is collaboration with external partners.

The operational and financial performance of the business is part of the S&OP process and needs to be communicated to the business within the cadence of meetings. Therefore, it is necessary to define the process owner and active participants from other functions such as supply chain, sales, marketing, manufacturing and finance. The roles and responsibilities for each participant within the process should be clearly defined.

Proven research and experience show that companies from different industries, sizes and business models are only able to have an excellent or developing S&OP process if it is sponsored by the highest level (CEO or COO) and if top management is very well informed and actively involved.

4. Monitoring

Monitoring is the last, but no less important dimension. It is fundamental for every S&OP process step and for management meetings such as S&OE (Sales & Operations Execution), Pre-S&OP and Executive Meeting to have well defined metrics and well-structured analysis processes.

Metrics need to be value driven and can include FVA (Forecast Value Added), service levels to customers, out-of-stock and wastage costs, total supply chain costs and distribution. Therefore, the company must have an active governance model for these metrics and their definitions, calculations and data sources.

A critical key to effective S&OP is the decision-making process, which in turn can be supported by the business intelligence branch called Analytics, defined by the applied use of data, analytics and systematic reasoning to gain insights into actions to be taken.

Analytics is inserted in and around the S&OP process and is used for needs assessment and sophisticated dynamic predictive analytics, as well as scenario planning and optimisation. It should often be used for predictive modelling, using external variables and causal relationships to explain what will happen and how this helps in organisational decision making.

Ricardo Toledo

Business Consultant at Wysupp

14 June 2021